الحار منتجات

ملكنا الإخبارية

coldrolling مطحنة workrol

Cold work rolls (hardness and material of cold work rolls)

2023/8/28 (2)In the quadruple cold rolling mill, most of the work rolls have a crown, and the backup rolls are cylindrical. If the total crown is not large, only the upper work roll has a crown, and the lower work roll is cylindrical. If

获取价格

Cold Mill Work Rolls - Union Electric Åkers

Extensive range This market segment covers forged Work Rolls and Intermediate Rolls for use in Wide Cold Strip Mills of 2-high, 4-high, or 6-high types, including reversing Reduction Mills,

获取价格

Fundamentals of Roll Cooling and Control of Flatness at

roll bite and in a typical Cold Tandem Mill, work roll temperatures normally fall in the range of 55oC – 70oC with strip recoil temperatures and inter-stand strip temperature rarely exceeding

获取价格

Navigating the Crucial Roles of backup Rolls and Work Rolls in

2024/2/27 The work rolls are in direct contact with the rolled product. The back-up roll supports the work roll. By contacting the work roll with the workpiece, the diameter of the work

获取价格

Work Rolls and Backup Rolls - LMM GROUP - Rolling mill rolls leader

Founded in 2007, LMM GROUP mainly produces all kinds of metallurgical rolls for various types of steel, bar, high-speed wire and strip hot and cold plate and strip rolling mills. The company

获取价格

Sundwig 6-high cold rolling mill - Andritz

The diameter of the 6-high work rolls amounts to approximately 1:4 in relation to the barrel length. In comparison to a 4-high mill stand, the utilization range is wider. This type of rolling mill is

获取价格

Sundwig 4-high cold rolling mill - Andritz

Product description. The Sundwig 4-high mill is equipped with positive and negative work roll bending in order to influence the shape and the flatness of the strip. Either the work roll or the

获取价格

Leading Manufacturer of work roll LMM GROUP

As a provider of high-durability work roll, LMM GROUP ensure our products are built to last. Our rolls undergo rigorous testing to guarantee they can withstand the toughest operating

获取价格

High-quality Work Roll Manufacturing Technology Using New

1 KOBELCO TECHNOLOGY REVIEW NO. 30 DEC. 2011 High-quality Work Roll Manufacturing Technology Using New Electro Slag Remelting (ESR) Jun SATO *1, Kouji IWANAGA ,

获取价格

Cold Rolling - ASSAB Global

Cold Rolling. Many different processes are used in the manufacturing of metal parts in cold condition, such as blanking and forming, punching, shearing, cold forging, cold extrusion,

获取价格

Cold Mill Rolls Work Rolls Backup Rolls Backup

Psrolls - We are manufacturer of rolls and roll assemblies complete with bearing assemblies other components manufacturing. cold mill rolls, work rolls, backup rolls, backup rolls sleeves, induction hardened rolls. rolls for cold rolling mills,

获取价格

(PDF) Ribbon Fatigue Spalling of a Forged Work

2014/10/31 Catastrophic failure of a forged work roll used in a cold rolling mill was investigated. The spalled roll showed fatigue arrest marks in a smooth continuous path along the circumferential direction.

获取价格

Work roll bending forces in 4-roll mills - ResearchGate

Download scientific diagram Work roll bending forces in 4-roll mills from publication: Hot rolling mill hydraulic gap control (HGC) thickness control improvement In this article the AGC ...

获取价格

Cold Rolling Mill - Tenova

Work Roll Size: 400 mm x 1430 mm Backup Roll Size:1250 mm x 1430 mm Separating Force:1800 Tons Mill Speed: 1250 m/min Mill Stand Features: Hydraulic Screw-down, Roll Bending-Mae West, Roll Changer, Pass-Line Wedge Adjustment, Spindle Supports, Side Guides Pressure Board, USC Zone Controlled Coolant Sprays, Doctor Knife,

获取价格

Explore the core role of backup rolls and work rolls in the cold ...

2024/2/27 The symmetry of the two parallel planes of the work roll drive flat head relative to the work roll axis, the radial runout of each step on the roll neck relative to the roll neck, the symmetry of ...

获取价格

Optimization of multi‐segment work roll profile for 1340mm HC

2023/6/28 To address issues with saturated work roll bending force (WRB), maximum contact pressure between the work roll and intermediate roll (QWI), and challenging flatness lifting in a four‐stand, six ...

获取价格

Navigating the Crucial Roles of backup Rolls and Work Rolls in Cold Rolling

2024/2/27 The work rolls are in direct contact with the rolled product. The back-up roll supports the work roll. By contacting the work roll with the workpiece, the diameter of the work roll can be reduced and the stiffness of the work roll can be enhanced. Cold rolling rolls are the main components of cold rolling mills.

获取价格

Analysis and Countermeasures of Spalling of Cold Rolling Back

2021/7/23 The fatigue cracks extend to the surface and finally spall.In the cold-rolled strip production process, although the back-up roll does not directly contact the strip steel, most of the huge rolling force exerted by the strip steel on the cold-rolled work roll is transmitted to the back-up roll, and the back-up roll has to bear a lot of Bending ...

获取价格

Overview of work rolls for cold rolling - ResearchGate

2000/1/1 The effects of a slow heating rate and a long austenitizing time with various cooling rates on the carbide dissolution and phase transformations of a 5% Cr work roll steel was investigated based ...

获取价格

Effect of rolling parameters on cold rolling of thin strip during

2003/9/22 The problem of work roll contact at the edges should be considered in an analysis of the cold rolling of thin strip, which forms a new deformation feature. In this case, the models of deformation and mechanics are different from the

获取价格

Experimental study on wear and friction of work roll material with

2011/7/29 In cold rolling, the surface of the work roll is subjected to high pressure, friction and thermal stress. The roll surface at the bite can be subjected to pressure over 1000 MPa and an interfacial shear stress generated by friction [3].The life of a cold work roll is limited by the deterioration of the surface finish due to wear through fatigue-based mechanisms, which

获取价格

(PDF) IMPROVEMENT OF OPERATIONAL EFFICIENCY OF COLD

2019/7/28 the work roll campaign showed that the average tem-perature in stand No. 1 was 73 °C, in stand No. 2 - 72°C; in stand No. 3 - 69°C, and immediately after removal .

获取价格

Optimization of Multi‐Segment Work Roll ... - Wiley Online Library

2023/6/28 To address issues with saturated work roll bending force (WRB), maximum contact pressure between the work roll and intermediate roll (QWI), and challenging flatness lifting in a four-stand, six-high tandem cold mill with a 1340 mm width, the density-based spatial clustering of applications with noise algorithm and the non-dominated sorting genetic algorithm

获取价格

Effect of rolling parameters on cold rolling of thin strip during

2003/9/22 The problem of work roll contact at the edges should be considered in an analysis of the cold rolling of thin strip, which forms a new deformation feature. In this case, the models of deformation and mechanics are different from the

获取价格

Experimental study on wear and friction of work roll material with

2011/7/29 In cold rolling, the surface of the work roll is subjected to high pressure, friction and thermal stress. The roll surface at the bite can be subjected to pressure over 1000 MPa and an interfacial shear stress generated by friction [3].The life of a cold work roll is limited by the deterioration of the surface finish due to wear through fatigue-based mechanisms, which

获取价格

(PDF) IMPROVEMENT OF OPERATIONAL

2019/7/28 the work roll campaign showed that the average tem-perature in stand No. 1 was 73 °C, in stand No. 2 - 72°C; in stand No. 3 - 69°C, and immediately after removal .

获取价格

Optimization of Multi‐Segment Work Roll ... - Wiley Online Library

2023/6/28 To address issues with saturated work roll bending force (WRB), maximum contact pressure between the work roll and intermediate roll (QWI), and challenging flatness lifting in a four-stand, six-high tandem cold mill with a 1340 mm width, the density-based spatial clustering of applications with noise algorithm and the non-dominated sorting genetic algorithm

获取价格

Hard chrome plating of work rolls for cold rolling and skin-pass

2014/7/12 A. Work rolls are subject to such enormous composite stresses that a perfect balance between internal flexibility, outer hardness and toughness, thermal resistance, wear resistance and thickness of hard layer is essential. This last concept associated with roll life is normally measured in inches (or large fractions of an inch), not thousands, like chrome.

获取价格

IMPROVEMENT OF OPERATIONAL EFFICIENCY OF COLD

mill a significant number of damages of the work roll barrels and roll failures caused by surface delamination was recorded. In addition, high roll consumption was reported. Roll consumption at the 4-stand mill was 30% higher compared to the 5-stand cold rolling mill. All of that required a comprehensive analysis of the process

获取价格

Experimental study on wear and friction of work roll material with

2011/7/29 The work roll used in rolling mill plays a significant role on the strip shape and rolling costs. It is one of the principal sources for running the plant. It is estimated that roll consumption accounts for approximately 25% of operational costs in cold rolling, which means that it is vital to low cost and high quality cold rolling production. ...

获取价格

What is Cold Rolling – Advantages and Disadvantages

1. High Pressure Requirements: The pressure required in cold working is very high. 2. Reduction in Size is Less: The reduction in size per pass is very less in cold working process.

获取价格

Mill Rolls - WHEMCO

WORLD CLASS ROLLS OF THE HIGHEST QUALITY FOR OVER 100 YEARS. The WHEMCO companies in Pennsylvania and Ohio, USA manufacture a full range of mill rolls – spun cast iron, cast steel and forged steel.

获取价格

Damage resistance and roughness retention of work rolls in

a work roll in a controlled laboratory en-vironment, fully equipped with measure-ment devices. In order to evaluate the level of damage within a pilot mill work roll, a tailor-madetest righasbeenbuilt byLismar for in-line non-destructive testing (NDT) of the pilot mill work rolls. The rig contains a sensor head that scans the work roll with

获取价格

Cold Mill Work Rolls - Union Electric Åkers

Extensive range This market segment covers forged Work Rolls and Intermediate Rolls for use in Wide Cold Strip Mills of 2-high, 4-high, or 6-high types, including reversing Reduction Mills, Tandem Mills, Double Reduction Mills, and Temper/Skin Pass Mills. Our Rolls can be supplied in a number of grades to suit various applications, materials, and rolling conditions.

获取价格

Review on cold rolling mill roll deformation - IJOER

The work roll of 20 Hi rolling mill generally maintains 50 – 55 HRc up to 4-5 mm depth. This hardness is to be achieved by hardening operations. The furnace used for this purpose either is salt bath furnace or induction based furnace. The hardness is also based upon the quenching method. In cold rolling mill rolls the

获取价格

Mechanics of Cold Rolling of Thin Strip - IntechOpen

Mechanics of Cold Rolling of Thin Strip 443 where yiw is the vertical deflection of the work roll at element i, gijw (, ) is the influence function for the work roll deflection due to the combined bending and shear forces generated by rolling load, giwf is the influence function for the work roll deflection due to the force generated by the roll bending mechanism, k represents the minimum element

获取价格

Cold Rolling of Steels - IspatGuru

2014/10/8 Cold Rolling of Steels. satyendra; October 8, 2014; 3 Comments ; annealing, Cold rolling, double reduction mill, hot rolling, Pickling, reversing mill, skin pass mill, tandem mill,; Cold Rolling of Steels The primary purpose of cold rolling of steels is to reduce the thickness of the hot rolled steel strips (normally in the range of 1.5 mm to 5 mm) into thinner thicknesses

获取价格التشحيم كسارة الدوران متفوقة

شركات تعدين سمر الشرقية

مطاحن الرياض سطيف اسباب الافلاس

معدات التبغ الصناعي

تجهیزات معادن اجاره

قيود معالجة المعادن

مصنع تكسير التنين تي كوم

فصل سحق الحجر

آلة بيع تعدين الذهب في جنوب أفريقيا

ملف تعريف الشركة لمعدات التعدين

فيلم مصنعي كسارة الكلينوزوايت

للبحث في تحسين قوة المعالجة الاستفادة من شيتسيشان

الكسارات المتنقلة في دوبيا جبل علي

تستخدم خام النحاس في أفريقيا كسارة الصخور المحمولة

Dwt Babcock آلة طحن نهاية الأنابيب

أنواع من الشاشة الاهتزازية

أبعاد المغذية فورانو عموم

آلة طاحونة الإعصار لمسحوق الحجر في الهند

كسارات صغيرة إيطاليا

مطرقة خط معالجة كسارة الفحم

أبيض مسحوق الحجر الأبيض آلات مصنع الفحم الروسية

كريسويل مصغرة الذهب المكثف

كسارة vip manjapra

واجبات ومسؤوليات مستشار محطة تكسير الصخور

معالجة سحق الفلسبار

ميتسوي المستخدمة سطح طحن للبيع

حول لدينا

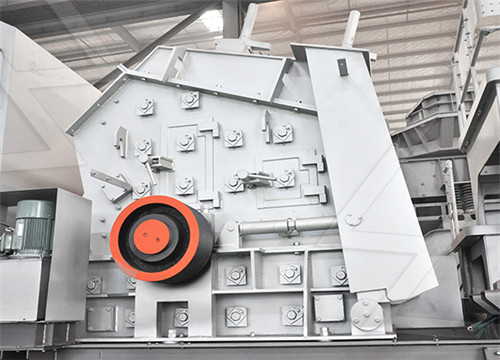

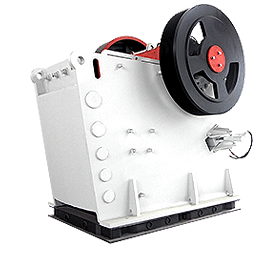

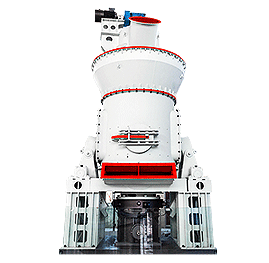

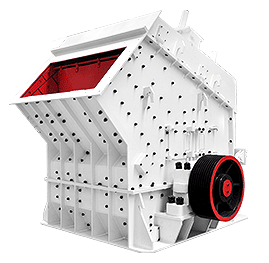

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20