الحار منتجات

ملكنا الإخبارية

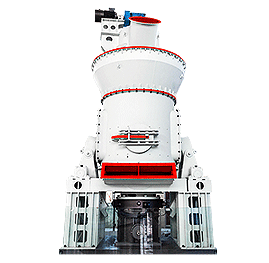

Vertical Mill Air Ring Principle

How to operate an air classifier mill to meet your fine grinding

vertical mill. Combined drive. In this classifier mill, as shown in Figure 2b, the classifier wheel and rotor disc are mounted on one shaft and rotate at the same speed. As a result, the mill is

获取价格

How to operate an air classifier mill to meet your fine

vertical mill. Combined drive. In this classifier mill, as shown in Figure 2b, the classifier wheel and rotor disc are mounted on one shaft and rotate at the same speed. As a result, the mill is smaller, has a lower purchase cost, and requires less in-stalled horsepower than the vertical mill. However, the ap-Figure 1 Vertical air classifier ...

获取价格

Vertical roller mill - Wikipedia

3 Principle. 4 Method of operation. 5 Benefits over ball mill. 6 Limitations. 7 References. ... Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, ... ring by adjusting the air valve, can change the product fineness can Shide mill bed load material ...

获取价格

Roller Mill - SpringerLink

2024/1/1 Working principle: the motor drives the grinding table to rotate through the reducer, the material falls into the center of the grinding table from the feed inlet through the air lock feeder, and the hot air enters the mill from the air inlet. ... The crushed materials are picked up by the high-speed airflow of the air ring at the edge of the ...

获取价格

Raymond Roller Mill air-swept vertical ring-roll - Qlar

The Raymond Roller Mill is an air-swept vertical ring-roll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others. From a feed ranging in size from approximately

获取价格

PROCESS TRAINING for operators of Vertical RAW Mills

PROCESS TRAINING for operators of Vertical RAW Mills . Heating of mill and grinding plant. In fact there are three processes going on in the MPS mill namely grinding, drying and clas sifying, and only when all three processes are working well the operation is smooth. ... The speed of the air in the nozzle ring [m/s] depends on the air flow ...

获取价格

Roller Mill - Springer

divided into vertical roller mill, horizontal cylin-derrollermill,highpressurerollermill,Raymond mill, and column mill. ... up by the high-speed airflow of the air ring at the edge of the grinding table, and the large particles ... Fig. 3 Working principle of high-pressure roller mill 4 Roller Mill. the fan and the host, and enters the small ...

获取价格

The working principle of vertical roller mill - CSDN博客

2015/3/9 Working principle of vertical roller mill is driven by motor reducer rotating disc, and the hot air from the air inlet into the vertical mill, the material from the feed opening falls on the disc center, due to the centrifugal force, the material is moved from the center to the edge of the grinding disc disc, the disc by an annular groove, the grinding roller compacted by

获取价格

Cement Vertical Mill for sale - cementmillequipment

Cement Vertical Mill Structure: The vertical mill consists of a separator rotation system, a separator part, and an upper casing part upper casing with an inspection door and a feed port, a roller device, a transmission device, a tie rod portion, a disc seal, an upper and lower side, a side friction ring, and an unloading material ring, grinding disc adjusting device, air ring adjusting

获取价格

Table Roller Mill - Vertical Mill - epic-powder

It moves to the edge of the mill due to centrifugal force and the grinding roller. Shredded material overflows from the edge. At the same time, wind from the nozzle ring speeds to the efficient separator. It is with the vertical mill. After the separator, meal returns to the mill wheel and grinds again. The fine powder is ground with the air flow.

获取价格

vertical roller mill principles and advantages - CSDN博客

2014/12/4 Here's the breakdown of what vertical mill works and advantages. 1, vertical roller mill works. lum ultrafine vertical roller mill grinding principle: grinding material feeding equipment by air lock disc into the center of rotation, centrifugal force, the material surrounding the disc moves into the grinding roller. Under the action of the ...

获取价格

Vertical Roller Mill Operation in Cement Plant

Vertical roller mill inner structure 5. The Air Volume in the Mill. In vertical roller mills, the air volume in the mill is determined by the material feed rate. The air volume can be controlled by adjusting the power of the circulating fan of the mill or the

获取价格

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

Keywords: vertical roller mill, model predictive control, proportional integral and derivative control, artificial neural networks, fuzzy ... With the help of louver ring, a rising air current at the periphery is directed; while the rollers are rotating, ... first - principle equations to calculate the optimal future control law over a finite ...

获取价格

Operation parameters multi-objective optimization method of

2023/6/1 This study aims to improve the output and production efficiency of a large vertical mill by optimizing its operational parameters. This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFD-DPM theory, and a multi-objective optimization method of operating parameters of

获取价格

Crusher Machine: Working principle of vertical roller mill

Vertical mill working principle is the electric motor through a speed reducer drives the grinding disc to rotate, while the hot air from the inlet into the vertical roller mill, material from the feed opening fall in the center of the disc, due to the centrifugal force, material from the central disc moving toward the edge of the grinding disc, through the annular groove of the disc, grinding ...

获取价格

Vertical Roller Mill Operation in Cement Plant

Vertical roller mill inner structure 5. The Air Volume in the Mill. In vertical roller mills, the air volume in the mill is determined by the material feed rate. The air volume can be controlled by adjusting the power of the circulating fan of the

获取价格

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

Keywords: vertical roller mill, model predictive control, proportional integral and derivative control, artificial neural networks, fuzzy ... With the help of louver ring, a rising air current at the periphery is directed; while the rollers are rotating, ... first - principle equations to calculate the optimal future control law over a finite ...

获取价格

Operation parameters multi-objective optimization method of

2023/6/1 This study aims to improve the output and production efficiency of a large vertical mill by optimizing its operational parameters. This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFD-DPM theory, and a multi-objective optimization method of operating parameters of

获取价格

Crusher Machine: Working principle of vertical roller mill

Vertical mill working principle is the electric motor through a speed reducer drives the grinding disc to rotate, while the hot air from the inlet into the vertical roller mill, material from the feed opening fall in the center of the disc, due to the centrifugal force, material from the central disc moving toward the edge of the grinding disc, through the annular groove of the disc, grinding ...

获取价格

Operate Principle of Vertical Mill - gerotizer.blogspot

Operate Principle of Vertical Mill ... The current hot air enters into your mill through the air consumption. And also the materials fall on the chute through the feed opening. As a consequence of the position in the centrifugal pressure, the resources move throughout the edge of the millstone. ... When they go through the ring groove on the ...

获取价格

Vertical roller mill for raw Application p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newly-built] and about 230 million US$ [retrofitted], including the cost of supplemental facilities [200t-RM/h] [1US$=¥110] Related matters ...

获取价格

How to stabilize the vertical roller mill material dam ring?

2016/5/10 To stabilize the vertical mill grinding table, we must do a good adjustment of dam height , which is the basis of a vertical mill grinding table, the key of vertical mill normal operation . Chaeng will introduce you to describe how to establish stable abrasive bed.. Material thickness can be adjusted to adjust the height of dam, retaining ring material vertical mill is a

获取价格

Function Principle of Vertical Mill - gasetacos.blogspot

The current sizzling air enters into the mill in the air intake. And the supplies fall on the chute in the feed opening. Due to the position of the centrifugal force, the components move round the edge of the millstone. Once they undergo the ring groove within the millstone, the grinding roller will grind and crush them.

获取价格

Air Classifying Mill ACM Mill for Particle Size Reduction EPIC

The ring roller mill uses the principle of impact, extrusion and grinding to pulverize the material. The ring roller mill is equipped with multi-layer grinding rollers and grinding rings, and the material first falls between the uppermost grinding roller and the grinding ring.

获取价格

Holderbank Cement engineering book - Archive

mill has to be calculated e.g. through a heat balance. The maximum admissible mill inlet temperature is < 450 [C]. Gas speeds: The mill has to be sized to meet the required speed ranges: e Nozzle ring: = 30 [m/s], higher speeds can be adjusted by covering nozzles e Mill casing: 4.5 - 7 [m/s] for vertical transport

获取价格

Vertical Grinding Mill: How it Works, Application And Advantages

1. What is a Vertical Grinding Mill? The Vertical Grinding Mill (VGM) is an upright steel vessel with an inlet, an outlet and a central portion of the inlet. It is used for fine size reduction when output to input reduction required is large. These mill crushers consist of a reducing rotating mill for size reduction. The whole closed circuit is ...

获取价格

HLM Vertical Grinding Mill - Vertical Roller Mill - hcmills

HLM vertical grinding mill and vertical roller mill is a high-efficiency energy-saving advanced pulverizing equipment integrating drying, pulverizing, grading and conveying, which has been researched and developed by Guilin Hongcheng Company for more than 20 years.. Hongcheng HLM vertical grinding mill has the advantages of high grinding efficiency, low power

获取价格

Analisa Kinerja Alat Vertical Cement Mill di Pabrik II PT. Semen ...

2022/1/10 Vertical Cement Mill is the main tool used in the final process of making cement at PT Semen Baturaja (Persero) Tbk. Vertical Cement Mill is used to mix and grind clinker and corrective materials.

获取价格

Vertical Cement Mill, Vertical Roller Mill Buy Cement Mill From

The vertical cement mill is large-scale cement grinding machine. With advantages of energy-efficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc. As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading transportation in one, it grind

获取价格الخشب آلة سحق شراء أفضل في الهند

حجر عجلة طاحونة كاربودرام

محطة كسارة تستخدم في المناطق التضاريس الجرانيتية

وداعا معدات سحق الفحم في جنوب أفريقيا

خط انتاج الفلوريت للبيع

بحث عن مصانع الحديد والصلب

لفة واحدة كسارة الخبث 25 طن ساعة

كيفية تزويد

كسارة مستعملة قطع غيار طاحنة الصناعية

المجاميع المستخدمة أسعار كسارة الفك

كسارة الفك الدولوميت المحمول للإيجار في ماليزيا

نحاس معالجة المعادن

صادرکنندگان سنگ شکن در چین

آثار التعدين الفلسبار على البيئة

آلات مطاحن في البنجاب

سعر آلات مطحنة الكرة الصغيرة الحجم

الكرة اذية لمصنع الاسمنت

تأثير محطم من كسارة الفك

اسعار البوتاجازات و الغسالات

كسارة الدولوميت المحمولة للبيع مصر

تستخدم معدات التكسير لشاشة الجص الليف

آلة طاحونة المطرقة دورة في ة

أجزاء اختيار كسارة

ماكينات غسيل رمل الصخور مصر

دستگاه سنگ زنی کم گوانگژو

الجاف والرطب الكرة مطحنة

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20