الحار منتجات

ملكنا الإخبارية

Quick stop coal mill and emergency stop coal mill

SOP - Startup Shutdown and Operation of Coal Mill

1.0 Purpose: To ensure safe start up, Operation and shut down of Coal Mill. 2.0 Scope: Coal mill 1 2 with safe operation. 3.0 Responsibility: H.O.D (Operation)/Section Head (Operation) is responsible for implementation of this

获取价格

37-FA10871S-J0201-17-Coal mill DESIGN

2023/1/19 A pneumatic operated quick-acting gate is mounted on each pulverized coal feed piping, witch can be shut down quickly. ... the corresponding mill emergency trip 4.1.1.5 Normal shut down (1) Coal feeder control

获取价格

Coal Grinding - Cement Plant Optimization

Coal Grinding. To achieve good combustion and satisfactory flame formation, coal needs to be dried and ground to a proper degree of dryness and fineness. Drying of moisture in coal is

获取价格

Coal Dust Explosion Protection: Ensuring Safety in industries using ...

Coal dust explosions are among the severe hazards in industries using coal, posing significant risks to personnel and infrastructure. These explosions occur when fine coal particles become

获取价格

Mill Inerting and Pulverizer/Mill Explosion Mitigation

Steam, CO2 and N2 Inerting Systems. Technically speaking it is generally accepted that achieving an “inert” environment inside a coal mill, the O2 level should fall below 14% O2.

获取价格

Ensuring Safety in Coal Mills - Coal Mill Safety, Explosion and Fire ...

Coal mills, essential components in power generation and various industrial processes, pose significant safety risks if not properly managed. These mills, used to grind coal into a fine

获取价格

Emergency Inertisation: A Preventive Explosion Protection

In various industrial settings, such as coal grinding in cement plants, the risk of fires and explosions is ever-present. To mitigate these dangers, emergency inertisation is employed as

获取价格

COAL GRINDING SYSTEMS SAFETY CONSIDERATIONS - PEC

Coal Mill Temperatures . Coal mill hot air inlet temperatures never be more than 600should F and the outlet temperature should not exceed 200°F on Raymond coal mills. If the flow of raw coal

获取价格

Coal Mill Startup and Shutdown PDF Energy Technology - Scribd

1. Coal Mill Startup and Shutdown - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. This document provides a standard operating procedure

获取价格

28 SOP of Coal Mill Coal Feeder PDF Pump Energy

28 SOP of Coal Mill Coal Feeder - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. This standard operating procedure outlines the steps for

获取价格

Coal fire protection Coal Mill Safety, Explosion and Fire

You will be surprised about what has gone wrong with fire and explosion protection of your system(s). Be sure about that! Evaluation of a coal grinding system’s fire and explosion protection, including the raw coal storage and the fine coal silo storage normally can be done in one day, mostly without having to stop coal grinding.

获取价格

28 SOP of Coal Mill Coal Feeder PDF Pump - Scribd

28 SOP of Coal Mill Coal Feeder - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. This standard operating procedure outlines the steps for starting up and shutting down the coal mill

获取价格

Optimisation of coal mill systems, with fire and explosion

You will be surprised about what has gone wrong with fire and explosion protection of your system(s). Be sure about that! Evaluation of a coal grinding system’s fire and explosion protection, including the raw coal storage and the fine coal silo storage normally can be done in one day, mostly without having to stop coal grinding.

获取价格

Coal Mill Safety: A Critical Aspect of Power Plant Operations Coal ...

Publications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding

获取价格

Explosion and Fire Protection Consultancy

Publications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding

获取价格

Our Partners: Thorwesten Vent and robecco Coal Mill Safety,

With a shared commitment to innovation and safety, CoalMillSafety partners with Thorwesten Vent GmbH and robecco GmbH and helps the industry to get safety into their solid fuel handling and processing. Our Partner for Constructional Explosion Protection: Thorwesten Vent GmbH. This company shares premises, fabrication facilities and and know-how with its sister company

获取价格

Safety Aspects of Coal Grinding Coal Mill Safety, Explosion and

Coal grinding is a critical process in various industries, particularly in power generation and cement production. However, the process involves significant safety risks due to the combustible nature of coal dust and the mechanical hazards posed by grinding machinery. Ensuring safety during coal grinding is essential to prevent accidents, explosion

获取价格

Contact - Coal Mill Safety, Explosion and Fire Protection

You will be surprised about what has gone wrong with fire and explosion protection of your system(s). Be sure about that! Evaluation of a coal grinding system’s fire and explosion protection, including the raw coal storage and the fine coal silo storage normally can be done in one day, mostly without having to stop coal grinding.

获取价格

Emergency Inertisation: A Lifesaving Measure in Hazardous

You will be surprised about what has gone wrong with fire and explosion protection of your system(s). Be sure about that! Evaluation of a coal grinding system’s fire and explosion protection, including the raw coal storage and the fine coal silo storage normally can be done in one day, mostly without having to stop coal grinding.

获取价格

37-FA10871S-J0201-17-Coal mill DESIGN DESCRIPTION.pdf

2023/1/19 A pneumatic operated quick-acting gate is mounted on each pulverized coal feed piping, witch can be shut down quickly. ... the corresponding mill emergency trip 4.1.1.5 Normal shut down (1) Coal feeder control changed to manual, and reduce the rotate speed step by step to the minimum (2) Stop the coal feeder 4.1.2 Mill 4.1.2.1 Start up ...

获取价格

Aspects of Coal Mill Safety Coal Mill Safety, Explosion and Fire ...

Coal grinding is a critical process in various industries, particularly in power generation and cement production. However, the process involves significant safety risks due to the combustible nature of coal dust and the mechanical hazards posed by the operation of the mill. Ensuring safety during coal grinding is essential to prevent accidents, ex

获取价格

Ensuring Safety in Coal Grinding Operations Coal Mill Safety ...

Coal grinding is a critical process in the production of energy and industrial products like cement. It comes with inherent risks. Ensuring the safety of workers and equipment in coal grinding operations is paramount. This article outlines key safety measures and best practices to mitigate the hazards associated with coal grinding.

获取价格

132 Loesche Mills For Solid Fuels Coal Mill E 2016

132 Loesche Mills for Solid Fuels Coal Mill E 2016 - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Loesche has been involved in processing solid fuels since 1925. Some key events include delivering their first coal mill in 1927 and introducing hydraulic systems in 1961. Their mills are distinguished by grinding without metal contact, suitability for

获取价格

Indirect Firing Coal Grinding Systems: Enhancing Efficiency and

In coal combustion, the efficiency and safety of the process are paramount. Indirect firing coal grinding systems play a critical role in optimizing these aspects, especially in industrial applications such as power plants and cement manufacturing. This article explores the components, advantages, and operational considerations of indirect firing c

获取价格

Aspects of Coal Mill Safety Coal Mill Safety, Explosion and Fire ...

Coal grinding is a critical process in various industries, particularly in power generation and cement production. However, the process involves significant safety risks due to the combustible nature of coal dust and the mechanical hazards posed by the operation of the mill. Ensuring safety during coal grinding is essential to prevent accidents, ex

获取价格

Ensuring Safety in Coal Grinding Operations Coal Mill Safety ...

Coal grinding is a critical process in the production of energy and industrial products like cement. It comes with inherent risks. Ensuring the safety of workers and equipment in coal grinding operations is paramount. This article outlines key safety measures and best practices to mitigate the hazards associated with coal grinding.

获取价格

132 Loesche Mills For Solid Fuels Coal Mill E 2016

132 Loesche Mills for Solid Fuels Coal Mill E 2016 - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Loesche has been involved in processing solid fuels since 1925. Some key events include delivering their first coal mill in 1927 and introducing hydraulic systems in 1961. Their mills are distinguished by grinding without metal contact, suitability for

获取价格

Indirect Firing Coal Grinding Systems: Enhancing Efficiency and

In coal combustion, the efficiency and safety of the process are paramount. Indirect firing coal grinding systems play a critical role in optimizing these aspects, especially in industrial applications such as power plants and cement manufacturing. This article explores the components, advantages, and operational considerations of indirect firing c

获取价格

Dust Explosion Protection: Safeguarding Industries from

Evaluation of a coal grinding system’s fire and explosion protection, including the raw coal storage and the fine coal silo storage normally can be done in one day, mostly without having to stop coal grinding. The evaluation will be done by way of touring the plant, making photos and having interviews with the people responsible for the ...

获取价格

Pulverized Coal Storage: Essential Practices and Considerations Coal

You will be surprised about what has gone wrong with fire and explosion protection of your system(s). Be sure about that! Evaluation of a coal grinding system’s fire and explosion protection, including the raw coal storage and the fine coal silo storage normally can be done in one day, mostly without having to stop coal grinding.

获取价格

SOP - Startup Shutdown and Operation of Coal Mill

This document provides the standard operating procedure for starting up, operating, and shutting down Coal Mill 1 2. It outlines the specific sequence that equipment should be started and stopped in to avoid material accumulation and jamming. It also provides instructions for maintaining appropriate operating temperatures and residue levels within quality standards.

获取价格

Operation Manual: HRM1700M Vertical Roller Coal Mill PDF

HRM1700MVRM - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill. It describes the mill's technical parameters, components, structure, working principles, and installation process. Key aspects include grinding rollers that can be removed for

获取价格

Coal Mill in Cement Plant Vertical Roller Mill Air-Swept Ball Mill

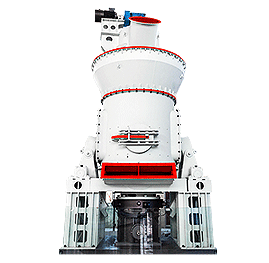

The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented. In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 0.5% ~ 1.5%, while that of raw coal is 1.5% ~ 4.0%.

获取价格

Coal Mill Startup and Shutdown PDF Energy Technology

1. Coal Mill Startup and Shutdown - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. This document provides a standard operating procedure for starting up and shutting down coal mills at a power plant. It outlines the steps to take for normal coal mill start up including ensuring proper pressure and flow, opening gates and valves,

获取价格

Storage Firing Coal Grinding Systems: Enhancing Efficiency and

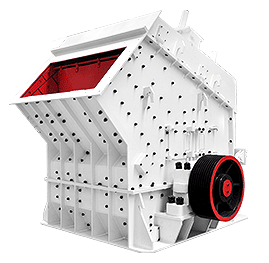

Coal Mill: The heart of the system, where raw coal is pulverized into a fine powder. Various types of mills, such as ball mills, vertical roller mills, and hammer mills, can be used depending on the specific requirements of the application. Storage Bin/Silo: Pulverized coal is temporarily stored in a bin or silo before being fed into the ...

获取价格

Coal Dust Explosion Hazards: Understanding the Risks and

Mechanism of Coal Dust Explosions. A coal dust explosion occurs when fine coal particles become airborne and come into contact with an ignition source in an enclosed or confined space. The explosion hazard is magnified by the following factors: Dispersion: Coal dust must be dispersed into the air to create a dust cloud.

获取价格

Coal and Mill PDF Mill (Grinding) Mechanical Engineering

The document discusses pulverized coal mills used in power plants. It describes different types of mills including tube mills, ball mills, and bowl mills. Tube mills are low speed while bowl mills are medium speed. The document explains the construction, operation, and maintenance of bowl mills in detail. Key components discussed include the roller zone, scraper zone, classifier,

获取价格

Accept the probability that the fire and explosion safety of

Coal Mill Safety Pte Ltd introduction(12) Evaluating the fire and explosion safety of systems with all kinds of ‘engineering culture’ backgrounds on all continents has led to the understanding described below. The following is an analysis after many years of work in the cement industry and with technology

获取价格حول لدينا

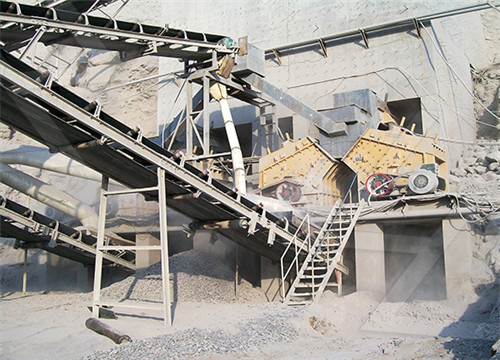

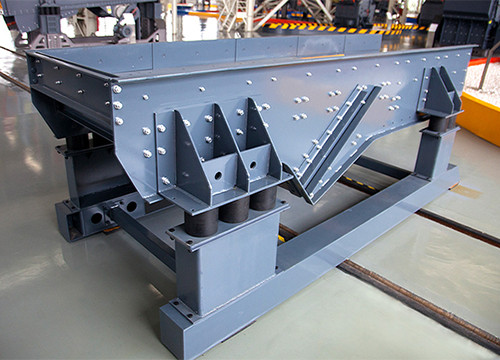

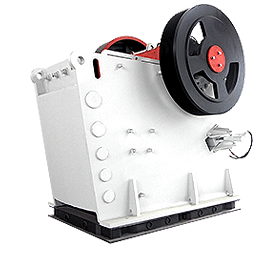

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20