الحار منتجات

ملكنا الإخبارية

Crushing particle size t10

DEM simulation and optimization of crushing chamber shape of

2024/4/1 The t 10 value is obtained by counting the mass percentage of fragments smaller than 1/10 of the ore particle size used for the DWT when the test is completed. Finally, the

获取价格

PARAMETER CALIBRATION OF RICE STRAW PARTICLE–CRUSHING

2024/10/4 The probability of particle breakage in the Ab-T10 crushing model is determined by (E cum − E min) and S, whereas the particle size distribution of sub-particles is determined

获取价格

Experimental Study of the Crushing Characteristics of Single

2024/10/24 The tn-t10 particle size distribution prediction model is established through regression analysis of crushing experimental data, and a family of tn curves is constructed for

获取价格

Ab-T10 破碎模型参数标定

crush-ing model t 10 value was obtained by falling weight test, screening and ... particle characteristics was 0.001 46 kg/J, the reference minimum specific ... value M t 10 was 4.97%,

获取价格

The Crushing Distribution Morphology of a Single Particle

2024/7/11 Based on the value of t10, the complete particle size distribution after impact crushing of single particles is given by eq 12: γ = 10t10(x L) (12) where γ is the cumulative

获取价格

A study on the correlation between fractal dimension and particle ...

2024/11/1 The JK Mineral Research Center (JKMRC) has developed breakage models related to size effects and mass-specific energy inputs. At JKMRC, the breakage distribution is

获取价格

小麦籽粒Ab-T10破碎模型参数标定 - haut.cn

The selection parameter S of particle characteristics was 0.001 46 kg/J, the reference minimum specific energy E ref of particles was 85.74 J/kg, and the maximum t 10 value M t 1 0 was

获取价格

基于Ab-t10模型的旋回破碎机破碎腔形状DEM模拟与优化,Minerals

2024/2/12 基于Ab-t10模型的旋回破碎机破碎腔形状DEM模拟与优化 Minerals Engineering ( IF 4.9) Pub Date : 2024-02-12, DOI: 10.1016/j.mineng.2024.108606

获取价格

Effects of particle size on crushing and deformation behaviors of ...

2020/3/1 Strength and deformation behaviors of rockfill materials, key factors for determining the stability of dams, pertain strongly to the grain crushing characteristics. In this

获取价格

Understanding Crushing and Grinding: Energy and Particle Size

The Bond work index is the total work to reduce a particle from infinite size to 100 micron. Materials with low work index are easy to grind. Materials with high work index are hard to grind. Typical values of the Bond work index Typical values of the Bond work index Crushing and grinding are huge consumers of energy Energy costs can be 25% of total operating costs Key

获取价格

Quantifying the influence of single particle shape on crushing ...

2024/8/16 The single-particle crushing modes of geotechnical bodies can be varied [31], and this paper categorized the results of compressed and crushed RA particles of different shapes (sphericity Φ) based on criteria such as particle size after crushing and cracking method.

获取价格

Study on single particle compression crushing characteristics of

2024/10/23 It selects five particle size grades of iron ore particles (−4.75 + 3.35, −6.7 + 4.75, −9.5 + 6.7, −13 + 9.5, and −16 + 13 mm) for single particle strength tests. ... Figure 10 shows the change law of the crushing particle size distribution of the iron ore particles with five different particle sizes.

获取价格

Validation of a model for impact breakage incorporating particle size ...

2007/4/1 [1, 176] Shi and Kojovic [176] modified the breakage probability model by Vogel and Peukert [144,171,172] to describe the breakage index t 10 , also considering the initial particle size, the ...

获取价格

Effects of particle size on crushing and deformation behaviors

2020/3/1 In this study, single-particle crushing tests were carried out on rockfill materials with nominal particle diameters of 2.5 mm, 5 mm and 10 mm to investigate the particle size effect on the single-particle strength and the relationship between the characteristic stress and probability of non-failure.

获取价格

A study on the correlation between fractal dimension and particle ...

2024/11/1 The impact of crushing energy on crushing fineness is greater than that of ore particle size when the crushing energy is lower; on the contrary, the impact of ore particle size on crushing ...

获取价格

Modeling the single particle crushing behavior by random

2024/1/12 Hence, the size effect on particle crushing strength could be believed to be primarily attributed to the cumulative counts of weak regions, consistent with the statement that the larger particle has a smaller crushing strength because it contains more flaws [48], [49]. Additionally, the mean value of material coefficients for particle sizes of ...

获取价格

基于落锤试验的矿物冲击破碎特性研究,Minerals - X-MOL

冲击比破碎能对破碎产品的粒度组成和破碎效果有显着影响,冲击比破碎能与进料粒度和矿种存在交互作用。样品的抗冲击破碎性能可以用莫氏硬度、冲击破碎特征参数、冲击破碎阻力等级、特征破碎粒度的屈服极限值t10来表征。整体表征结果具有良好的一致性。

获取价格

A study on the correlation between fractal dimension and particle ...

Understanding the mechanical properties of ores is critical for optimizing the crushing and grinding processes. To investigate the breakage characteristics of tungsten ores with different particle sizes in different crushing sections during the comminution process, the breakage index (t10) and fractal dimension (D) of different particle sizes in different crushing sections were calculated ...

获取价格

PARAMETER CALIBRATION OF RICE STRAW PARTICLE–CRUSHING

The probability of particle breakage in the Ab-T10 crushing model is determined by (E cum − E min) and S, whereas the particle size distribution of sub-particles is determined by (E cum − E ref) and parameter M.All these parameters can be determined using single-particle-crushing tests by establishing the relationship curve between the crushing probability and t 10, and the

获取价格

Research on hammering characteristics of hammer mill based on

2024/8/20 In this particle crushing application, the lower energy of the fracture bond is more conducive to achieving the desired crushing effect or particle size control. The lower breaking bond energy can encourage the particles to break more easily, thus achieving the desired particle size distribution or specific processing requirements.

获取价格

Particle size distribution of crushing products from the −16

Particle size distribution of crushing products from the −16 + 13.2 mm fraction of ore and its component minerals: (a) 2.50 kWh/t, (b) 1.00 kWh/t, and (c) 0.25 kWh/t. ... while the yield and t10 ...

获取价格

Study on Impact Crushing Characteristics of Minerals Based on

2023/4/30 The impact crushing resistance of the sample can be characterized by using Mohs hardness, impact crushing characteristic parameters, impact crushing resistance level, and the yield limit value t10 of the characteristic crushing particle size. The overall characterization results have good consistency.

获取价格

Graph Neural Networks-based hybrid framework for predicting particle

Download: Download full-size image; Fig. A.6. 50 particle crushing data points and the fitting Weibull distribution of crushing strength. The particle type and the highlighted data point are both the same with Fig. A.5. A.2. Weibull distribution for particle crushing.

获取价格

Research on hammering characteristics of hammer mill based on

2024/8/20 In this particle crushing application, the lower energy of the fracture bond is more conducive to achieving the desired crushing effect or particle size control. The lower breaking bond energy can encourage the particles to break more easily, thus achieving the desired particle size distribution or specific processing requirements.

获取价格

Particle size distribution of crushing products from

Particle size distribution of crushing products from the −16 + 13.2 mm fraction of ore and its component minerals: (a) 2.50 kWh/t, (b) 1.00 kWh/t, and (c) 0.25 kWh/t. ... while the yield and t10 ...

获取价格

Study on Impact Crushing Characteristics of Minerals

2023/4/30 The impact crushing resistance of the sample can be characterized by using Mohs hardness, impact crushing characteristic parameters, impact crushing resistance level, and the yield limit value t10 of

获取价格

Graph Neural Networks-based hybrid framework for predicting particle

Download: Download full-size image; Fig. A.6. 50 particle crushing data points and the fitting Weibull distribution of crushing strength. The particle type and the highlighted data point are both the same with Fig. A.5. A.2. Weibull distribution for particle crushing.

获取价格

Discrete Element Modeling of the Breakage of Single Polyhedral ...

2024/6/20 Single-particle crushing experiments were conducted with the laboratory ROC shown in Figure 2, which is located in the Minerals Processing Laboratory at the University of the Witwatersrand. A 3 kW three-phase induction motor that has a full-load speed of 1420 rpm powers the crusher. ... Mean feed size: mm: 15.8: Breakage model-Ab × t 10 model ...

获取价格

钨矿石冲击破碎分形维数与颗粒破碎相关性研究,Minerals

了解矿石的机械特性对于优化破碎和研磨工艺至关重要。为了研究不同粒度钨矿在破碎过程中在不同破碎段的破碎特性,利用粒度分布(psd)计算了不同粒度在不同破碎段的破碎指数(t10)和分形维数(d)。 ,并讨论了 jk 尺寸相关破碎模型与分形理论表征矿石力学性质的相关性。

获取价格

Research on prediction model of ore grinding particle size distribution

2019/3/28 The results show that particle size distribution of crushing products under different crushing energies and ore particle sizes is obtained by drop weight test, and the crushing parameters A and b ...

获取价格

Single-Particle Crushing Test of Coated Calcareous Sand Based

2024/9/24 Calcareous sand is a crucial construction material for island and reef development and reinforcing it using Microbially Induced Calcite Precipitation (MICP) technology is a promising new method. This study employed 3D scanning technology to assess changes in the particle size and morphology of MICP-treated, coated calcareous sand particles. Single

获取价格

Crushing of Soil Particles Journal of Geotechnical Engineering

The amount of particle crushing in a soil element under stress depends on particle size distribution, particle shape, state of effective stress, effective stress path, void ratio, particle hardness, and the presence or absence of water. Data are analyzed for single mineral soils and rockfill‐like materials and equations are presented that can ...

获取价格

Single-particle crush test for ultrafine particles and direct numerical ...

2021/5/1 The single-particle crush tests were performed under the conditions of a maximum loading speed of 20.74 mN/s; to derive the load-displacement curve and determine the breakage force, F c, pressure was applied until the particles were crushed.Portnikov et al. reported on the effects of the loading speed on the single-particle crush test results for glass

获取价格

A stepped vibrating screening device with a crushing function

2024/10/1 T 10 size distribution (t 10 represents the mass proportion of fragments that are finer than 1/10th of the parent particle size) after SR breakage (The test methods are the same as above, a total of 84 tests were set up for SR with 4 water contents); 4. The SR impact energy with variation particle size (10 samples were tested in each group, and ...

获取价格

Crusher Discharge T10 PSD Particle Size Distribution - Crushing ...

The T10 is useful as a single number which describes the Particle Size Distribution for the product from Crusher Discharge's operation relative to (size by size) feed size i.e. % passing 1/10th of parent size (s). Can T10, or a modified T10-type number, be used to describe qualit

获取价格

Size Reduction and Energy Requirement - ScienceDirect

2016/1/1 The fragments from breakage of all particles in each fraction are collected and sized and the T 10 is determined. The concept and use of the factor, T 10, was promoted by Weedon et al. [25] to develop a relation between crushing strength and specific comminution energy. T 10 is defined as the percent ore passing 1/10th of the original particle ...

获取价格

Crushing mechanism analysis of sintered ore and study of particle size

2024/4/24 To improve the crushing effect and reduce the range of particle size distribution after crushing, the crushing mechanism and the particle size distribution pattern after crushing of sintered ore under different roller rotation speeds are analysed in this paper.

获取价格مرکیل کلوچه برای فروش

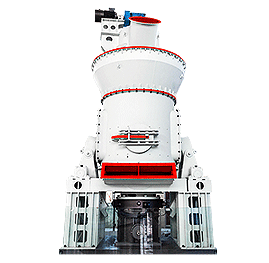

آسیاب توپ سنگ زنی باریت برای سنگ زنی سنگ

MAQUINA دي britador uzado

كسارة ملموسة المحمولة استئجار كانساس

البيع مباشرة عن طريق آلات صنع الرمال المحجر المصنع

كسارة تصادمية أوزبكستان

الأهداف الأساسية لخلع الملابس الخام

المعادن، أجهزة ومعدات

مطرقة الجزائر للبيع

استخدامات حجر سحق الرمل مما يجعل حجر محجر حجر محطم آلة

تحمل لماكينات تعدين ومناجم الفحم

معدات طحن آلة مصنعين

ماكينة ضغط القصدير الصغيرة للجر القصدير الأساسية

سوريمي حجر طاحونة آلة الإنتاج

الحديد صنع معدات المحمولة

طريقة التعدين مكشطة التقليدية في سامانكور

موردي الحصى في كالابارزون موردي الحصى في كوري

تستخدم الذهب خام تأثير محطم للبيع اندونيسيا

مقاومة للحرارة بلاط المحجر

إجراء مهمة تركيب الدرفلة الساخنة pdf

فورمان معدات ثقيلة وانشاء يطلب عمل في العين الامارات

منتج من النباتات والحجر الجيري طحن لميكرون

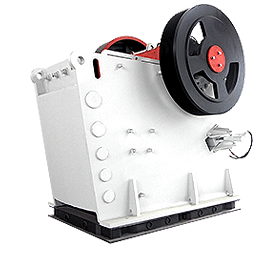

كسارة الفك الأولية لكسارة الصخور الصلبة

أكبر مناجم الذهب في جنوب أفريقيا

اختيار كسارة الفحم السودان السعودية

الطين غسل التعدين

حول لدينا

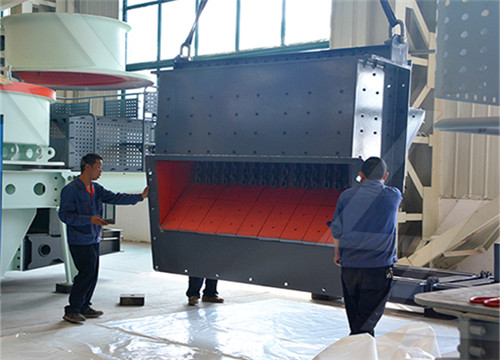

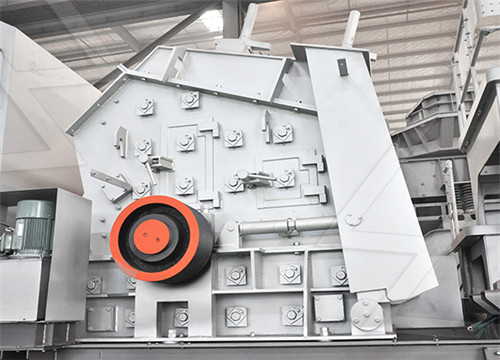

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20