الحار منتجات

ملكنا الإخبارية

raw mill operation techniques

23 Types of Milling Operations: Learn About Milling

2024/7/16 Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion. Follow me on: Milling operations are fast becoming a necessity in the manufacturing

获取价格

Rawmill - Wikipedia

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill. The raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the eff

获取价格

16 Types of Milling Operations Explained [with PDF]

2024/3/17 Milling is a popular machining process. Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. This method of subtractive manufacturing seeks to give the

获取价格

Raw milling and blending - INFINITY FOR CEMENT

Raw milling and blending ... Modern online techniques, outlined in Section 2.2, allow rapid correction and greatly reduced variation of mill product chemistry. ... The main difference to cement mill operation is the need to dry rawfeed and

获取价格

MILLING METHODS COMPARISON GUIDE - Custom

MECHANICAL MILLING. g/Pulverizing (and Pre-crushing)Coarse crushing may be required as a pre-milling initial step to reduce a material to a quarter-inch, the largest acceptable m. ll feed

获取价格

Understanding the Milling Process: A Comprehensive Guide to

2024/11/11 Milling has become essential in modern distribution, including using rotary cutters to cut a workpiece. This guide is intended to broaden the knowledge base regarding

获取价格

15 Types of Milling Operations - Xometry

2023/11/22 Here’s a picture of a thread made by thread milling: Thread milling. 5. Shoulder Milling. Shoulder milling removes material from the side of a workpiece (the “shoulder” or “sidewall”) with different cutting tools, like end

获取价格

Milling Technique - an overview ScienceDirect Topics

A substantial number of milling processes have been developed and tested until now, as well as specific machines for each type of technology. Various reviews have been published in the last

获取价格

CEMENT GRINDING COURSE - The Cement Institute

Learning outcomes An emphasis on the understanding of the milling technology system: Gas flow, advantage and disadvantage in the Raw mill and Cement mill installations – Grindability concept and the effects of inter-grinding materials of

获取价格

What Are the Types of Milling Operations: A Comprehensive Guide

Description: Side milling involves cutting with the side of the milling cutter to create a flat surface perpendicular to the axis of rotation. This operation is ideal for machining the sides of the

获取价格

Optimizing Maintenance Practices for Raw Vertical Roller Mills

2024/3/11 Raw vertical roller mills (VRMs) play a critical role in the cement manufacturing process, facilitating the grinding and drying of raw materials to produce the desired clinker. Effective maintenance of these VRMs is essential to ensure uninterrupted operation, maximize throughput, and minimize downtime.

获取价格

CEMENT GRINDING COURSE - The Cement Institute

Learning outcomes An emphasis on the understanding of the milling technology system: Gas flow, advantage and disadvantage in the Raw mill and Cement mill installations – Grindability concept and the effects of inter-grinding materials of

获取价格

Assessment of the thermodynamics efficiency of a cement vertical raw

A vertical raw mill plant operating at 240,000 kg per hour requires a process model containing physical property parameters. The vertical raw mill process consists of three steps: drying, grinding, and separation. An air stream transports fine particles entrapped in crushed raw materials upward in the upper part of the mill.

获取价格

SOP-startup Shutdown and Operation of Raw Mill PDF

SOP-startup shutdown and operation of Raw Mill - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. The document provides the standard operating procedure for startup and shutdown of raw mills at Anjani Portland Cement Limited. It outlines the sequence that various groups of the raw mill system should be started and

获取价格

Optimizing Raw Mills Performance ; the Materials WAY

2019/6/22 Introduction: Raw milling is one of the most important and integral component of cement production process; it is the stage which produces the most important intermediate product i.e.

获取价格

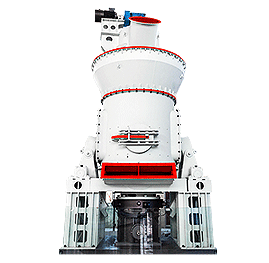

Raw mill - Cement Plant

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant.In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by

获取价格

23 Types of Milling Operations: Learn About Milling Processes

2024/7/16 Milling operations are fast becoming a necessity in the manufacturing world. From transforming raw materials into desired shapes, milling operation plays. Get Quote. Services. ... which is different from other milling techniques that typically involve rotary cutters. This method is especially useful for cutting long, straight cuts or grooves in ...

获取价格

Advanced feed mill procurement techniques - LinkedIn

2017/7/28 This article discusses about some of key procurement techniques that can be used to competitively source raw materials from suppliers to maximize the bottom line of the feed milling business: 1.1.

获取价格

Full article: Evaluation of optimization techniques for predicting ...

2021/7/5 The cement raw mill is the primary piece of equipment used in the modern cement industry for the raw meal production process. ... Shao et al. (Citation 2016) proposed an air distribution model using multi-objective optimization techniques developed to address the issue of heat recovery in a cement ... Figure 5a depicts a plot of the operation ...

获取价格

raw mill operation in limestone preparation.md

Contribute to lbsid/en development by creating an account on GitHub.

获取价格

A comprehensive review on Advanced Process Control of cement

2023/1/1 The rotary kiln operation incurs most of the plant’s operating cost (16%), as illustrated in Fig. 1. Pyro processing tower is another major energy-intense equipment used to preheat the raw material. Other milling equipment like the raw and cement mill also demands a high cost due to the complex nature of raw materials.

获取价格

Kiln Process Fan Vibrations Prediction Based on Machine Learning

Kiln process fans play a crucial role in the cement manufacturing process. This article presents a study on the use of machine learning models to predict kiln process fan vibrations based on process fan running parameters. The study tested three different models, namely, k-nearest neighbors, linear regression, and random forest, and it found that all three could accurately

获取价格

30 Mill Operator Interview Questions and Answers

2023/9/5 Any deviation could indicate an issue with milling parameters or raw materials. Testing is also crucial. This could involve laboratory tests like moisture content, protein levels, or ash content depending on the product. ... “To maintain high efficiency during milling operations, I prioritize regular preventive maintenance to ensure the ...

获取价格

Mastering Chainsaw Milling: Essential Tips for Perfect Cuts

2024/5/27 In conclusion, mastering chainsaw milling is an invaluable skill for anyone looking to transform raw logs into usable lumber with precision and ease. By following the 17 tips outlined in this guide, you can enhance your milling techniques, ensure your safety, and optimize the quality of your cuts.

获取价格

A comprehensive review on Advanced Process Control of cement

2023/1/1 The rotary kiln operation incurs most of the plant’s operating cost (16%), as illustrated in Fig. 1. Pyro processing tower is another major energy-intense equipment used to preheat the raw material. Other milling equipment like the raw and cement mill also demands a high cost due to the complex nature of raw materials.

获取价格

Kiln Process Fan Vibrations Prediction Based on

Kiln process fans play a crucial role in the cement manufacturing process. This article presents a study on the use of machine learning models to predict kiln process fan vibrations based on process fan running parameters. The study

获取价格

30 Mill Operator Interview Questions and Answers

2023/9/5 Any deviation could indicate an issue with milling parameters or raw materials. Testing is also crucial. This could involve laboratory tests like moisture content, protein levels, or ash content depending on the product. ... “To maintain high efficiency during milling operations, I prioritize regular preventive maintenance to ensure the ...

获取价格

Mastering Chainsaw Milling: Essential Tips for Perfect Cuts

2024/5/27 In conclusion, mastering chainsaw milling is an invaluable skill for anyone looking to transform raw logs into usable lumber with precision and ease. By following the 17 tips outlined in this guide, you can enhance your milling techniques, ensure your safety, and optimize the quality of your cuts.

获取价格

Machining Operations Explained - Engineering Cheat Sheet

2023/3/10 Machining Involves the use of various tools and techniques to remove material from a workpiece to create a desired shape or size. Machine shops employ machinery such as mills, lathes, and drill presses to remove material, as well as 3D printers to add material when necessary. ... raw or pre-fabricated stock to be machined to specifications ...

获取价格

Rawmill - Wikipedia

A medium-sized dry process roller mill. A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill.The raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the

获取价格

Root Cause Analysis of Rolls Bearings Failure in Vertical Raw Mill:

In the cement industry, the reliability and efficiency of equipment are critical to maintaining smooth operations. However, when equipment failures occur, they can lead to significant downtime and financial losses. This post delves into a specific case study of Rolls Bearings failure in a Vertical Raw Mill at the Kollenbach plant in Germany.

获取价格

Milling Made Simple: A Beginner’s Guide to CNC Milling

2023/4/13 Other milling operations; Numerous other milling operations exist, such as drilling, profiling, thread milling, plunge milling, angular milling, and slide milling. Material Selection for CNC Milling. You need to select the suitable material for a specific job to obtain the desired product’s desired quality and performance.

获取价格

Revolutionizing Feed Milling Processes: A Comprehensive

2022/8/4 Ultimately, this research paper serves as a guide for feed mill operators, researchers, and stakeholders to optimize feed milling processes and advance the livestock industry. Feed Mill Abu Rayhan ...

获取价格

Slot Milling: Diagram, Working, Types, Advantages Uses

2024/3/5 It is a machining procedure that uses a spinning tool with many cutting edges. A slot milling operation’s main determinants are the workpiece’s material properties and the necessary dimensions of the slot (width, depth, and undercut).. The proper selection of tools, feed rate, speed, and cooling fluids can all have a significant impact on the final quality of the

获取价格

how to control moisture in the limestone in the raw mill - LinkedIn

2024/7/15 Here are some strategies and techniques to manage and control moisture: 1. Controlling moisture in limestone within a raw mill is crucial to ensure optimal milling conditions and to prevent ...

获取价格

Heat Integration in a Cement Production IntechOpen

2018/10/10 There are two operation modes of the particular cement factory. The first one is when the raw mill is under operation and, in this case, the cooling water flowrate at the cooling tower is 3 t/h. A hot gas from the kiln is fed into the raw mill and a raw material is heated. The second operation mode presumes that the raw mill is out of operation.

获取价格

Everything you need to know about Operational Considerations

These factors, together with stronger emphasis on reducing mix variability for stable kiln operation, have called for better techniques in raw milling process and quality control. Moeller (1997) has reported a detailed account on the influence of raw material and fuel with respect to the burning process and the quality of clinker produced ...

获取价格

16 Types of Milling Operations Explained [with PDF] - The

2024/3/17 Milling is a popular machining process. Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. This method of subtractive manufacturing seeks to give the workpiece the desired shape. In milling operations, rotary cutting tools, typically equipped with multiple teeth or edges, are employed to precisely

获取价格سعر كسارة مخروطية فى مصر

كسارات الحجارة المصنعة في الهند

اتجاهات كسارة حبوب منع الحمل الفارس الصامت

جاي جاي ميلز سري الجندي معلومات الاتصال المحدودة

حار بيع pyb600 الألغام مجمع كسارة مخروطية

كسارات الحجارة المعدات اللازمة لبناء

الصحة والسلامة للالكسارات

الأعمال مصنع محطم في الإمارات العربية المتحدة

الحجر اللازمة لسحق الحجر للبناء

الصين المورد آلة فصل خام النحاس آلة التعويم للبيع

عمليات وجدت في خط

عالية لوحة الفك CORBON لكسارة الفك

فتح ة التعدين خام الحديد مع طحن وسحق، معدات الفحص المطلوبة

كسارة مخروطية محمولة لخام الحديد للإيجار في عمان

معدن شن و ماسه طبیعی

فحص النباتات لالحجارة

السيارات والتعدين جنوب أفريقيا

كسارة متنقلة لكسارة التعدين

200tph سحق سعر الجهاز

الشركة المصنعة لمعدات الاستحسان في مصر

المطاحن الكروية المنتجات كسارة

المرجع في خراطه المعادن

مرحلة واحدة المطرقة محطم مع معيار إسو

آلات التعدين تستخدم على نطاق واسع 30 طن ح طاحونة آلة

تعدين الذهب الأفريقي الحديث تعدين البوكسيت إجراء الحفرة المفتوحة

كسارة مخروطية 4ukt6n5y صغيرة

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20