الحار منتجات

ملكنا الإخبارية

copper concentrate plant production of carbonate

Copper Mining and Processing: Processing Copper Ores

A. Processing of Oxide OreB. Processing of Sulfide OreC. Recycling CopperOxide ores are generally processed using hydrometallurgy. This process uses aqueous (water-based) solutions to extract and purify copper from copper oxide ores at ordinary temperatures, usually in three steps: heap leaching, solvent extraction, and electrowinning. Heap Leachingis the process of using percolating 在superfund.arizona上8

(PDF) Processing of Complex Materials in the Copper

2020/7/6 4.—e-mail: galvear1963@hotmail. With the gradual decrease in the grade of copper ores being processed, copper. concentrates

获取价格

Novel approach for processing complex carbonate-rich copper

2021/1/15 As a result, the carbonate content of the ore often determines the processing route (i.e., leaching vs flotation). Depending on the carbonate content of the ore, acid consumption ranges from 0.4 to 0.7 tonnes H 2 SO 4 per tonne of copper recovered (Ambo,

获取价格

Chapter 6 Copper Production Technology - Princeton University

Chapter 6. Copper Production Technology. The last boomin technological innovation for the copper industry occurred in the first two dec- ades of this century, whenopen pit mining, flo- tation concentration,and the reverberatory smelter were adapted to porphyry copper ores. With the

获取价格

The fate of molybdenum in the residues of a Chilean copper ore ...

2022/6/15 For many elements and types of materials including slag, a possible re-processing has been studied and the literature is abundant. However, the focus and successful applications were mostly on e.g. copper and other base or precious metals, such as gold or platinum group elements (Drobe et al., 2021, Kraemer et al., 2015, Syed, 2012), while the

获取价格

Treatment of Mine Water with Reverse Osmosis and

2023/1/25 The new development (Figure 3 and Figure 4) involves the use of a membrane plant for the simultaneous purification of the wastewater and the utilization of the concentrate of the reverse osmosis plant with guaranteed

获取价格

Production of copper concentrate from sulfide ores

The production of copper concentrate from sulfide ores is a vital process in the copper mining and metallurgical industry. Copper sulfide ores, which contain significant amounts of copper in the form of minerals such as chalcopyrite,

获取价格

Jubilee Celebrates Copper Concentrate Production at Roan

2024/8/16 The start of copper concentrate production at this facility highlights Jubilee's ongoing commitment to expanding its capabilities and advancing its position in the metals industry. ... Plant Capacity, Production, Operating Efficiency, Demand Supply Gap, End-Use Application, Sales Channel, Regional Demand, Company Share, Manufacturing Process ...

获取价格

Carbon Footprint of Copper Production - International

2018 data, copper production1 represents approximately 0.2% of global GHG emissions, and while this contribution to global GHG emissions is currently low, copper demand is expected to double by 2050, driven in part by the need for copper for the clean energy transition. Given this awareness, copper miners and producers recognize that they have a

获取价格

Acid treatment of copper sulfide middlings and rougher concentrates

2008/8/1 This study involved the chemical and detailed mineralogical analysis of the final copper concentrate produced at the Lubin Concentrator, one of the concentrating plants of the Mining–Smelting ...

获取价格

Copper Sulfide Ore - an overview ScienceDirect Topics

Flotation of copper oxide minerals: A review. Qicheng Feng, ... Guang Han, in International Journal of Mining Science and Technology, 2022. 1 Introduction. The continuous development of the global economy has resulted in a high demand for copper production and high copper consumption [1,2], and exploitation and effective use of copper oxide mineral resources have

获取价格

Lithium processing technology Complete solutions that

comprising 1–1.5% Li20 to a concentrate of about 6–6.5% Li20. To achieve this, the ore passes through a typical concentrator-type plant, flowing from crushing and grinding, to gravity separation and DMS, to flotation, and then to the final dewatering of the

获取价格

Case study for production of calcium carbonate from carbon dioxide

2016/6/1 The steel plant produces ∼280,000 t per year of air-cooled AOD slag and ladle slag that would be readily available for use for calcium carbonate production. Work with the above-mentioned laboratory pilot has so far demonstrated production of rhombohedral calcite and aragonite from steelmaking slag, but attempts to produce scalenohedral ...

获取价格

Principles of Copper Production - ScienceDirect

2024/1/1 All these factors increase copper loss to slag, lowering the first-pass copper recovery. As a consequence, direct production of copper from concentrate in one step has been elusive and impractical, except for a few high-grade copper concentrates. 2.2.1.4. MATTE SMELTING AND CONVERTING STEPS. The term “smelting” has broad and narrow definitions.

获取价格

Precious metal content in copper concentrate and slag

2019/1/1 The superior conduction properties of copper makes it an essential material for the fabrication of wide range of electric equipments such as wiring and motors, as well as craft tools and weapons.

获取价格

Duro Felguera contracts the construction of a sodium carbonate ...

2023/6/21 Soda Ash is used, among other applications, in the extraction and smelting of metals, and very importantly in the production of lithium carbonate, used in lithium batteries in electric vehicles. The scope of the contract covers basic and detailed engineering, procurement, transport, civil works, electromechanical assembly, testing, operator ...

获取价格

Effective Removal of Arsenic from Copper Matte by Sodium Carbonate

2024/9/19 Residual arsenic in copper matte is a source of arsenic contamination in subsequent processes in the smelting section of copper pyrometallurgy. In order to solve the impact of arsenic in copper matte on the subsequent process of smelting, this study removes arsenic from copper matte by adding an arsenic removal agent to the molten copper matte.

获取价格

Copper Concentrate Leaching Developments by Phelps Dodge

2013/10/4 Leaching of copper from a Jordanian copper ore has been studied using a stirred batch reactor with hydrochloric acid as the main lixiviant, under the following conditions: temperature 25 – 45 oC ...

获取价格

Precious metal content in copper concentrate and

2019/1/1 The superior conduction properties of copper makes it an essential material for the fabrication of wide range of electric equipments such as wiring and motors, as well as craft tools and weapons.

获取价格

Duro Felguera contracts the construction of a sodium carbonate ...

2023/6/21 Soda Ash is used, among other applications, in the extraction and smelting of metals, and very importantly in the production of lithium carbonate, used in lithium batteries in electric vehicles. The scope of the contract covers basic and detailed engineering, procurement, transport, civil works, electromechanical assembly, testing, operator ...

获取价格

Effective Removal of Arsenic from Copper Matte by Sodium Carbonate

2024/9/19 Residual arsenic in copper matte is a source of arsenic contamination in subsequent processes in the smelting section of copper pyrometallurgy. In order to solve the impact of arsenic in copper matte on the subsequent process of smelting, this study removes arsenic from copper matte by adding an arsenic removal agent to the molten copper matte.

获取价格

Copper Concentrate Leaching Developments by Phelps Dodge

2013/10/4 Leaching of copper from a Jordanian copper ore has been studied using a stirred batch reactor with hydrochloric acid as the main lixiviant, under the following conditions: temperature 25 – 45 oC ...

获取价格

Copper recovery from copper slags through flotation enhanced

2022/6/1 Copper plays a vital role in modern life, which is irreplaceable for daily infrastructure and technologies [1], [2].However, despite the finite copper resources on the Earth, global copper production continued increasing over the past century [3], [4].Although we are far from approaching geological stocks for potentially mineable Cu resources, the economic

获取价格

Copper (II) Carbonate Manufacturing Plant Project Report 2024:

2024/10/28 Introduction. Copper (II) carbonate, also known as cupric carbonate, is an important chemical compound with various industrial applications. It serves as a key ingredient in agriculture, especially in fertilizers and fungicides, and plays a significant role in ceramics and pigment production.

获取价格

(PDF) Atmospheric leaching of copper flotation concentrate with ...

2011/1/1 Results of atmospheric leaching of copper sulphide concentrate from Lubin Concentrator (ZWR Lubin) with oxygenated aqueous H 2 SO 4 and in the presence of Fe(III) have been presented.

获取价格

Technology of Polish copper ore beneficiation - ResearchGate

2016/1/1 This study involved the chemical and detailed mineralogical analysis of the final copper concentrate produced at the Lubin Concentrator, one of the concentrating plants of the Mining–Smelting ...

获取价格

Copper Mining and Processing: Processing Copper Ores

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 99.99% pure copper called cathodes, which will ultimately be made into products for everyday use.The most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively,

获取价格

G. YONDON: A COPPER CONCENTRATE PROCESSING PLANT

2024/6/27 On April 29, the Mongolian Stock Exchange JSC successfully organized the first copper concentrate trading, and Erdenet Corporation sold a total of 3000 tons (wet weight) of copper concentrate with a copper content of 22.35%.

获取价格

Technology of Polish copper ore beneficiation –

collective concentrate of copper and molybdenum is heat treated before separation of copper from molybdenum. 2 Beneficiation technology of Polish copper ores - past experience and perspective 2.1 Characteristics of the ores The copper ore exploited and processed at KGHM Polska Miedz S.A. plants has a complex chemical

获取价格

Technological and economic strategies for the optimization of

2010/9/1 The main aim of the paper is to present possible strategies of copper production, which the processing plant can implement, resulting from the technological and economic (market) factors. ... Formulation of a relationship between copper concentrate grade and mass recovery is the major part of introduced model. ... in ore from mine 2 carbonate ...

获取价格

Kamoa Copper’s phase 1 concentrator plant: commercial production

2021/8/6 Kamoa Copper’s Phase 1, 3.8 Mtpa concentrator plant reached commercial production on 1 st July 2021 after achieving a milling rate in excess of 80% of design capacity and recoveries very close to 70% for a continuous, seven-day period. Copper production has steadily increased since first production began at the end of May.

获取价格

Acid treatment of copper sulfide middlings and rougher

2008/8/1 The beneficial effect of leaching of carbonate gangue from flotation middlings and rougher concentrates with sulfuric acid prior their final flotation has been presented. This process was effectively applied within the existing flotation circuit in order to facilitate floatability of difficult-to-treat carbonate black shale copper ores.The leaching of flotation feed with sulfuric acid ...

获取价格مجفف الفحم المصنعة المملكة العربية السعودية

اسعار ماكينة الصيد في جده

كومبينج أن بيع كسارة فكية في نيجيريا

مطاحن و كسارة فكية من تركيا

فاصل طبل مغناطيسي جاف لخام الحديد الهيماتيت فاصل مغناطيسي

طاحونة سير ذاتية الخام

دليل صيانة الكسارة الرائدة

أسعار المسحوق الرماد المتطاير

الصيغية الكيمياىية لأكسيد الحديد

مزايا أنواع التكسير

صيانة سحق الحصى مصنع

مطحنة الكرة غير منضبط

الشمسية محطة للطاقة الحرارية

مطحنة القرص ffc kapasitasukuran besar

أسعار مطحنة الكرة كسارة الفك مصر

مرافق معالجة المنغنيز في الجزائر

معالجة ونقل خام المنغنيز ميريونيث

محمول مزود الكسارة الفك الدولوميت في جنوب افريقيا

ايباي طحن مصغرة معدات للورش الميكانيكية

اماكن بيع مطاحن كربونات الكالسيوم فى الصين

مطحنة دقيق الحبوب

كسارة الحجر بيماسوك

كسارات تتبع مستعملة

مصانع الأسمنت في المنطقة ناجبور

مجال الشركات المصنعة كسارة الصخور في باكستان

تستخدم بيع محطم المستخدمة في إيطاليا

حول لدينا

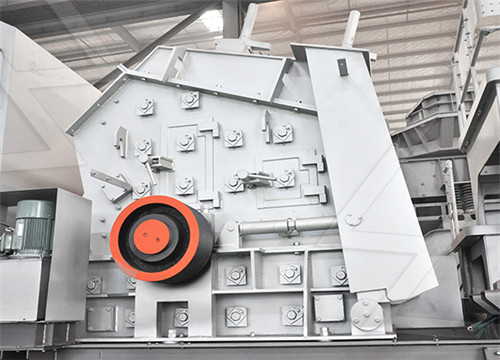

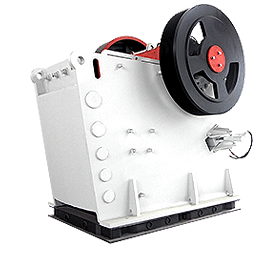

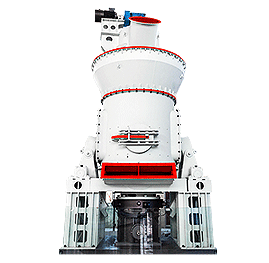

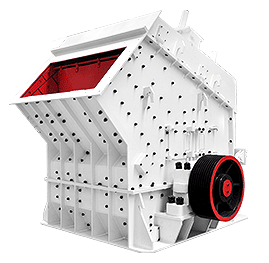

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20