الحار منتجات

ملكنا الإخبارية

ball grinding mill for tungsten process

Producing Metal Powder from Machining Chips Using Ball Milling

2023/6/27 A key component of the grinding process in a ball mill is the ball size distribution (BSD), which controls the grinding efficiency, product size distribution, and media wear rate. ...

获取价格

Grinding Media - Union Process

Parametric study on four station ball mill for synthesis of ultrafine ...

2023/4/28 The size of the grinding balls used in the ball mill can impact the milling process and the resulting particle size distribution. Changing the ball size can help optimize the milling

获取价格

The process and mechanisms for the transformation of coarse

2018/2/15 Tungsten powder and grinding balls were weighed by the precision balance (with the accuracy of 0.0001 ... In the later process of ball milling, the medium-sized tungsten

获取价格

Refinement process and mechanisms of tungsten powder by high

2017/4/1 The process uses a ball mill, a cylindrical chamber with a grinding medium such as balls that rotates on its axis to achieve the desired fineness of the final product [9,75].

获取价格

Tungsten Processing Equipment, Process Flow, Cases

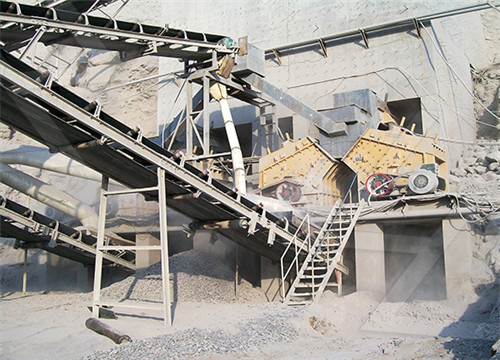

2019/8/23 wolframite, scheelite, bismuth and sliver. 【Extraction beneficiation】. Crushing – washing – hand picking – grinding – jig concentrator – shaker table – flotation – magnetic separation. complete processing flow

获取价格

Obtaining of tungsten nanopowders by high energy ball milling

2020/5/28 Abstract and Figures. The objective of the work is identifying the modes of ball milling of the W16,5 and PWT grade tungsten that ensure obtaining nanosized powders.

获取价格

Ball Milling of Tungsten Alloys Request PDF - ResearchGate

2001/1/1 The effects of some processing conditions (i.e. vial rotation speed, balls number and milling time) at the 16 : 1 ball-to-powder weight ratio on the tungsten powder aspect

获取价格

Effect of Ball Milling Parameters on the Refinement of

The high-energy ball milling method was adopted to explore the influence of ball milling parameters, such as milling speed and additive amounts of process control agent (PCA) on tungsten powder. The morphology and microstructure of

获取价格

Wet Batch Production Mills - Union Process

These versatile and easy-to-maintain grinding mills have been successfully used in a variety of industries to grind everything from chocolate to tungsten carbide. In addition, Attritors can be produced to meet the requirements of even the most

获取价格

Tungsten carbide sintered blank grinding ball

The high quality LAARMANN Tungsten carbide sintered blank grinding balls are usable Planetary Ball Mills. Tungsten carbide. Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing

获取价格

Study of integrated milling-grinding of microlens array on

2024/6/1 In this paper, an integrated milling-grinding machining method was used to fabricate MLA on binderless tungsten carbide. A model for predicting the relationship between surface roughness and undeformed chip thickness during the

获取价格

Demystifying the Ball Milling Process: Expert Insights - JXSC

2024/7/2 Step2 Rotation of the Cylinder: Once the materials have been fed into the ball mill, the cylindrical container begins to revolve on a horizontal axis. This rotation is done by a motor and drive system which is seen at the far end of the mill in the picture. The rotational speed can be adjusted to ensure that the grinding media and the material are lifted and cascaded in

获取价格

Producing Metal Powder from Machining Chips Using Ball Milling Process ...

2023/6/27 A key component of the grinding process in a ball mill is the ball size distribution (BSD), which controls the grinding efficiency, product size distribution, and media wear rate. ... and mechanisms of tungsten powder. The authors conducted a series of experiments using a planetary ball mill to refine tungsten powder and investigated the impact ...

获取价格

MSE PRO 1 mm Spherical Tungsten Carbide Milling Media Balls

1 mm Spherical Tungsten Carbide Milling Media Balls (Polished) Order qty. units: 10 balls, 100 balls, 1000 balls, 10000 balls, or 1000 g Density: 14.95 g/cm3 Shape: Spherical Character: Excellent abrasion resistance for ball milling of hard materials. Tungsten Carbide Grinding/Milling Media Balls Specifications Highly

获取价格

Ball Mill Success: A Step-by-Step Guide to Choosing the Right Grinding

2024/8/8 The selection of grinding media is a critical decision in the ball milling process, affecting not only the efficiency of the operation but also the quality of the final product. ... Choosing the right grinding media for ball milling involves a strategic assessment to align with operational goals, material characteristics, and cost constraints ...

获取价格

Planetary Ball Mill BM20 - Beijing Grinder Instrument Co.,Ltd

O-ring for 125 ml tungsten carbide grinding jar (small) 70.011.0007: O-ring for 125 ml tungsten carbide grinding jar (big) 1. For grinding jar of zirconium oxide /agate/sintered aluminum oxide material, a small and a big O-ring should be used at the same time. 2. Grinding balls please see the accessories for GT300.

获取价格

Planetary Ball Mills - Fine Grinding Solution - Across International

Planetary ball mills may be used for mixing, homogenizing, fine grinding, mechanical alloying, cell disruption, small volume high-tech material production, and even colloidal grinding. They are the ideal wet/dry milling tools for acquiring research samples with high efficiency and low noise. Vacuum jars may be used to process sample within a vacuum environment.

获取价格

Tungsten Extraction Process - 911Metallurgist

2016/3/10 The Peripheral Discharge Rod Mill permits rapid discharge with minimum contact time and therefore this mill is ideal for limiting the number of fines in the ball mill discharge. After the middling product is quickly ground to liberate additional minerals, it is then re-jigged to recover the additional high-grade tungsten.

获取价格

Inventory Of Common Faults And Solutions Of Mining Ball Mill

2024/11/11 Reason: This is a common problem mining ball mills face, resulting in low productivity and low ore processing efficiency. One reason may be the improper design of the grinding chamber, which affects the flow of materials and reduces grinding efficiency. Additionally, worn or damaged liners can hinder the grinding process by reducing the effective impact

获取价格

High-energy ball milling of WC-10Co: Effect of the milling

2022/4/1 Ball milling is a key step in the processing of tungsten carbide parts. It ensures a good distribution of the different powders and reduces the crystallite size in the nanometer range by “mechanical alloying”. The study of the influence of the rotation speed and the milling medium on the sinterability of the WC-Co composite is important. The optimization of milling was

获取价格

Cryogenic Planetary Ball Mill - Korea Process Technology

under low temperature process. Air cooling system The air cooling system has advantages of ... Mill Jar Balls : PTFE Grinding method : Dry grinding Rotation speed : 450rpm Total volume : 1Llx4=4L ... alumina mill balls, PU mill balls, steel carbon mill balls,tungsten mill balls, etc. Material Volume of Mill Jar Diameter of Mill Ball Stainless ...

获取价格

Versatile Planetary Ball Mill Upto 4 Grinding Stations

Planetary Ball Mill BM 1400+ (4 Grinding Stations) ... Colloidal milling, Mechanical alloying Up to 4 (With 4 grinding platforms can process 2, 4, 8 samples simultaneously) Integrated 7" Touch Display with all digitally adjustable speed, Grinding time, Holding/Pass time, Interval operation etc. ... (Stainless Steel, Agate, Zirconium Oxide ...

获取价格

Inventory Of Common Faults And Solutions Of Mining

2024/11/11 Reason: This is a common problem mining ball mills face, resulting in low productivity and low ore processing efficiency. One reason may be the improper design of the grinding chamber, which affects the flow of

获取价格

High-energy ball milling of WC-10Co: Effect of the milling

2022/4/1 Ball milling is a key step in the processing of tungsten carbide parts. It ensures a good distribution of the different powders and reduces the crystallite size in the nanometer range by “mechanical alloying”. The study of the influence of the rotation speed and the milling medium on the sinterability of the WC-Co composite is important. The optimization of milling was

获取价格

Cryogenic Planetary Ball Mill - Korea Process Technology

under low temperature process. Air cooling system The air cooling system has advantages of ... Mill Jar Balls : PTFE Grinding method : Dry grinding Rotation speed : 450rpm Total volume : 1Llx4=4L ... alumina mill balls, PU mill balls, steel carbon mill balls,tungsten mill balls, etc. Material Volume of Mill Jar Diameter of Mill Ball Stainless ...

获取价格

Versatile Planetary Ball Mill Upto 4 Grinding Stations

Planetary Ball Mill BM 1400+ (4 Grinding Stations) ... Colloidal milling, Mechanical alloying Up to 4 (With 4 grinding platforms can process 2, 4, 8 samples simultaneously) Integrated 7" Touch Display with all digitally adjustable speed, Grinding time, Holding/Pass time, Interval operation etc. ... (Stainless Steel, Agate, Zirconium Oxide ...

获取价格

MSE PRO 4 mm Spherical Tungsten Carbide Milling Media Balls

Description for 4 mm Spherical Tungsten Carbide Milling Media Balls (Polished) Order qty. units: 1 ball, 100 balls, 1000 Balls, or 1 kg Density: 14.95 g/cm3 Shape: Spherical Character: Excellent abrasion resistance for ball milling of hard materials. Tungsten Carbide Grinding/Milling Media Balls Specifications Highly p

获取价格

Tungsten Carbide Balls for Enhanced Grinding - planetary ball mill ...

2024/11/12 Among the various tools and materials used for grinding and milling, tungsten carbide balls have emerged as a game-changer, offering unparalleled performance and durability. This article delves into the advantages and unique characteristics of our company’s tungsten carbide balls, providing a comprehensive overview and a case study to ...

获取价格

Tungsten Carbide Rod Manufacturer, Tungsten Carbide End Mill, Tungsten

Tungsten carbide division: Specialize in producing hard alloy ball gears, brazing sheets, wire-drawing dies, roll collars, cold heading dies, mineral alloy, shield blades, litchi surface hard alloy bits, serrated fins, wood cutting blades, milling, tungsten carbide plates, rods, punching dies, customized products.

获取价格

Cast Grinding Balls vs. Forged Grinding Balls: Making the Right

2024/10/25 The forging process itself is celebrated for producing grinding balls that not only meet but exceed the demands of high-impact and precision grinding tasks, setting a high standard for efficiency and reliability in industrial milling operations.

获取价格

MSE PRO 3 mm Tungsten Carbide (WC-Co) Balls for Grinding and Milling

2020/6/17 Description for 3 mm Tungsten Carbide (WC-Co) Balls for Grinding and Milling, 1 kg. Product SKU#: BA0649 Excellent wear and abrasion resistance for ball milling and grinding of hard materials. Tungsten Carbide Grinding and Milling Media Balls Descriptions. Highly quality tungsten carbide milling media with good wear-resistance and chemical stability against acid

获取价格

Effect of Ball Milling Parameters on Properties of Nano-Sized Tungsten

2024/9/20 Nano-sized tungsten exhibits superior properties due to its high-density grain boundaries’ strengthening. The high-quality nano-sized powder is essential for sintering nano-sized tungsten bulks through powder metallurgy techniques. In this study, nano-sized tungsten powder was successfully synthesized by mechanochemical methods using mixed WO3 and

获取价格

LABORATORY GRINDING MILLS - Union Process

mill." The operation of an Attritor is simple and effective. The material to be ground is placed in a stationary tank with the grinding media. Carbon steel, stainless steel, chrome steel, tungsten carbide, and ceramic balls are commonly used media. The material and media are then agitated by a shaft with arms, rotating at high speed.

获取价格

grinding of tungsten ore Mining Quarry Plant

2013/4/1 Tungsten ore grinding mill in tungsten mining process is widely used in chemical industry, etc. Shanghai kefid can manufacture ball grinder mill,

获取价格

Refinement process and mechanisms of tungsten powder by

2017/4/1 The process uses a ball mill, a cylindrical chamber with a grinding medium such as balls that rotates on its axis to achieve the desired fineness of the final product [9,75].

获取价格أنظمة تجميع الغبار من الصين لمعدات التكسير

يمكن استخدام كسارة الفك في تعدين الماس

طاحونة ماسالا الحجر الكهربائي

الخبث سحق المعدات المورد من

الكلنكر وحدة طحن في الهند بيع

كسارة دريوال portabel

كفاءة عالية وجودة كسارة وخلاط charal

آلة تجفيف الحمأة

المتنقلة سحق آلات الحجر من النمسا

حلقة مسطحة الرطب المغناطيسي الفاصل في فرز الأوحال التنغستن

تكلفة الاستثمار أو مطحنة الكرة

آلة إثراء وفصل الذهب من الخامات

الرأسي الخام الرسوم المتحركة مطحنة في فلف ريموند مطحنة

نوع جديد من محطة كسارة الصدم المحمولة

كسارة المطرقة الصغيرة كسارة المطرقة كسارة متنقلة صغيرة

مقدمة لنوع جديد من الكاشطة طحن الجهازأتريتور خلط مطحنة

منجم الذهب الخاص بك قد انهار

تكسير الحجر محطم الرسوم المتحركة

تهتز التطبيقات كسارة مخروط

كرات سحق الخصي أشرطة الفيديو المجانية

عملية تكرير التنتالوم pdf

تصميم لاو خارج الفك محطم النبات

كسارة الفك الفحم الطاحن

آلات التكسير في أستراليا

مطحنة تكوير قشر الأرز الصغيرة في كينيا

پردازش تجهیزات سنگ آهن

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20