الحار منتجات

ملكنا الإخبارية

Mine crushing processing technology index

Crushing in Mineral Processing - 911Metallurgist

2015/12/26 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock (geometallurgy) to be

获取价格

Crushing and Screening Handbook - AusIMM

TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents Metso’s Mining and Construction Technology 1 Quarry Process + Process Integration and Optimization

获取价格

Technology improvements of crushing process in Majdanpek

1996/3/1 Crushing reconstruction in Majdanpek Copper Mine enables the introduction of automatic control system of secondary and tertiary crushing process. It enables the reduction

获取价格

AT CRUSHING TECHNOLOGY 2024

The CRUSHING TECHNOLOGY provides a comprehensive tabular overview of all stationary and mobile crushing plants, which are used in a wide range of applications in the extraction and processing of minerals. For example, this

获取价格

Influence of Basalt Aggregate Crushing Technology on Its

2023/1/8 Table 3 and Table 4 and Figure 6 show the geometric structure of the mineral grains after crushing in both types of crushers, with a division by the type of feed that was

获取价格

A review of modeling and control strategies for cone crushers in

2021/8/15 For this reason, state of the art cone crusher control technology in the mineral processing industry seems to be lagging; the crushing stage is overlooked because it is only a

获取价格

Mineral Processing Technology Roadmap - Department of

Mining Industry of the Future Mineral Processing Technology Roadmap Introduction 'Everything in the 21st century begins with mining.' Taken from the Future Begins with Mining: A Vision of

获取价格

Modeling and Improving the Efficiency of Crushing

2023/5/16 Over the last few decades, the demand for energy-efficient mineral-processing methods has continued. The necessity to develop energy-efficient technologies for the mineral industry will increase in the future,

获取价格

SIZE REDUCTION BY CRUSHING METHODS

2017/3/4 There are two kinds of. equipments used for crushing work s. one is by using crushers and other one is by using impacto rs. This diagram illustrates the stages of s ize reduction from 1000mm to 4 ...

获取价格

Wills' Mineral Processing Technology, 8th Edition

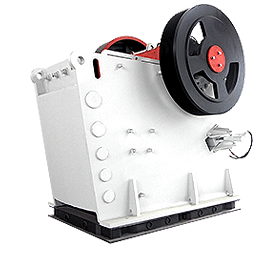

Chapter 6 Crushers Crushing is the first mechanical stage in the process of comminution in which a principal objective is the liberation of the valuable minerals from the gangue. Crushing - Selection from Wills' Mineral Processing Technology, 8th Edition [Book]

获取价格

Optimal energy management for a jaw crushing process in deep mines

2014/4/1 Numbi et al. (2014) have demonstrated that applying optimal energy management to a mining crushing process can result in more than a 50% energy cost reduction. Kusakana (2015b), has applied an ...

获取价格

Mineral Processing Equipment for Mining Industry

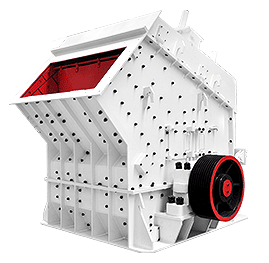

2024/8/7 Types of Mineral Processing Equipment. Crushing Equipment: Essential in mineral processing, crushing breaks down large ore blocks into smaller, manageable pieces for further processing. . Primary crushing is the reduction of significant ore particles into smaller bits using jaw crushers. Key types include Jaw Crushers, which handle large rocks ...

获取价格

Influence of Natural Aggregate Crushing Process on

Sustainability 2021, 13, 8353 2 of 15 Crushing processes are applicable in various fields of raw material processing, where the activities are carried out depending on which mineral aggregates ...

获取价格

Discussion on Crushing Theory in Gold Processing Industry

2021/1/21 6.Evaluation Index of Crushing Process Crushing Processing Capacity. It is expressed in terms of the amount of ore processed per unit time, t/h, to evaluate the crushing process quantitatively. Crushing Efficiency. The crushing efficiency is usually defined as the number of tons of crushed products obtained per 1 kwh of energy consumed.

获取价格

Optimal energy management for a jaw crushing process in deep mines ...

2014/4/15 Mining sectors account for about 15% of the total electrical energy consumption in South Africa, of which gold mining leads with 47% followed by platinum mining, taking 33% whilst 20% is consumed by the remaining mines. 1 It is further indicated that processing occupies the second place in mining energy consumption within the country with 19% of the total

获取价格

Discussion on Crushing Theory in Gold Processing Industry

2021/1/22 6.Evaluation Index of Crushing Process Crushing Processing Capacity. It is expressed in terms of the amount of ore processed per unit time, t/h, to evaluate the crushing process quantitatively ...

获取价格

Bond Work Index Formula-Equation - 911Metallurgist

2013/7/15 What is the Bond Work Index Formula-Equation? In case you had forgotten, here is a classic: You can read all the details of this now “Biblical” grinding power requirement calculation formula in Fred Bond’s original paper.. You can also review the step-by-step Bond Work Index Test Procedure I posted here.. See this useful summary Table of Bond Work

获取价格

Influence of Basalt Aggregate Crushing Technology on Its

2023/1/8 A higher flakiness index after the crushing process for non-cubical particles and a lower one after the crushing of flaky particles;- ... Based on these observations, the structure and composition of the rock should be considered when selecting mineral aggregate production technology, apart from the expected geometrical characteristics of the ...

获取价格

Correlation of crushing work index and drop-weight index.

Ore hardness can be estimated using commercially available standard techniques such as the SAG Power Index (SPI), Bond Work Index (BWI), and JK Drop Weight (JKDW) tests (Bailey et al., 2009 ...

获取价格

Mineral Processing PPT - SlideShare

2014/5/15 F = size of the screen opening ( microns ) through which 80% of the feed passes. Wi = The Bond Ball Mill Work index ( 1952 )- is a measure of the resistance of the material to crushing and grinding . A Bond Ball Mill Work Index test may be required for the design of a new mineral processing plant .

获取价格

(PDF) Comminution in mineral processing - ResearchGate

2018/11/19 The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market. Generally, the ability of treating crude material from excavation into mineral ...

获取价格

PowerMaster launches technology for crushing and ... - Mining

2024/8/2 The definitive guide to mining operations and excellence. Established in 1909 by Herbert Hoover, Mining Magazine provides comprehensive technical insight into mining operations. It aims to inform and support mine management in decision-making regarding mining techniques, technologies, workforce, logistics, and supply chains.

获取价格

Manganese ore crushing equipment processing technology - CM Mining ...

The manganese ore processing technology mainly includes three processes: crushing, grinding and beneficiation.During the crushing process, the three-stage closed-circuit crushing is the most modern and suitable for the crushing of high hardness manganese ore, which can complete the work of ore crushing and partial dissociation, thereby ...

获取价格

Mineral Processing PPT - SlideShare

2014/5/15 F = size of the screen opening ( microns ) through which 80% of the feed passes. Wi = The Bond Ball Mill Work index ( 1952 )- is a measure of the resistance of the material to crushing and grinding . A Bond Ball Mill Work

获取价格

(PDF) Comminution in mineral processing

2018/11/19 The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market. Generally, the ability of treating crude material from excavation into mineral ...

获取价格

PowerMaster launches technology for crushing and ... - Mining

2024/8/2 The definitive guide to mining operations and excellence. Established in 1909 by Herbert Hoover, Mining Magazine provides comprehensive technical insight into mining operations. It aims to inform and support mine management in decision-making regarding mining techniques, technologies, workforce, logistics, and supply chains.

获取价格

Manganese ore crushing equipment processing technology - CM Mining ...

The manganese ore processing technology mainly includes three processes: crushing, grinding and beneficiation.During the crushing process, the three-stage closed-circuit crushing is the most modern and suitable for the crushing of high hardness manganese ore, which can complete the work of ore crushing and partial dissociation, thereby ...

获取价格

5 Stages of Graphite Processing - Mining-pedia

The process of graphite beneficiation is mainly: crushing-grinding-separation-middling treatment-tailings treatment. 1. Crushing. The hardness of graphite ore is generally medium-hard or medium-hard to soft. The grade of the raw ore is between 2-10%, and the crushing process is relatively simple.

获取价格

Use of rock mechanical properties to predict the Bond crushing index

2007/6/1 The crushing energy in mineral processing industry is usually determined by empirical Bond’s index, regardless of the mechanical properties of a rock.

获取价格

Mineral processing - Wikipedia

Crushing, a form of comminution, one of the unit operations of mineral processing. Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. [1] Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.. Beneficiation is any process that improves (benefits) the

获取价格

Mineral Processing Technology Roadmap - Department of

Mining Industry of the Future Mineral Processing Technology Roadmap Introduction 'Everything in the 21st century begins with mining.' Taken from the Future Begins with Mining: A Vision of the Mining Industry of the Future, developed by the mining industry in September 1998, these words communicate the critical but often unseen role that mining plays in the economy and the lives

获取价格

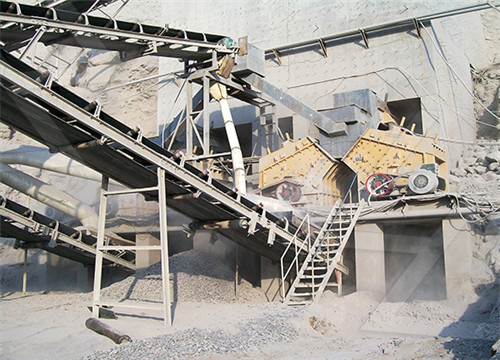

1500-10000t/h Semi-Mobile Gyratory Crushing Station-TYHI

Semi-Mobile Gyratory Crushing Station is a key equipment with semi-continuous mining technology (Single bucket shovel-truck-crushing station-belt conveyer).This system is suitable for the primary crushing of ore or rock in large open-pit mine, crushing the bulky material into appropriate size for belt conveyor. ... Rated process capacity: 1500t ...

获取价格

Innovation in mineral processing - North American Mining

2023/2/26 Coarse particle flotation and bulk ore sorting are starting to make waves in the mineral processing industry. North American Mining takes a look at both technologies with the help of experts from three leading mineral processing OEMs. ... “The diversion technology, crushing technology and the bulk material handling technologies are other key ...

获取价格

Rock Crushing Process in Mining - 911Metallurgist

2015/7/18 The primary roll crushers and the hammer mill cannot crush such rocks economically but are particularly useful with the relatively soft, friable and sticky rocks that are characteristic of many nonmetallic mineral deposits. Crushing is an integral portion of the comminution flowsheet for mineral processing operations and is critical for the ...

获取价格

SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

2017/3/4 Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by ...

获取价格

Compare and Understand Rod/Ball/Impact-Crushing/Abrasion BOND Work Index

2015/11/23 Anyone wondering how Bond ball mill work index compares versus SPI or JK A*b? Well, M. Doll says, several comparisons have been published, such as at CMP 2011 and Procemin 2009 and in general, the Wi_BM is not compatible with the other two because they measure different size classes. The Bond ball mill work index measures the grindability in the

获取价格

Optimizing Coal Processing: Mining, Crushing, Screening,

2024/6/19 The content provides a comprehensive overview of coal processing, covering mining, crushing and sizing, screening, washing, drying, sorting and blending, etc.

获取价格أنشطة التعدين الحالية في فيجي قمة جديدة

مطحنة عطا مطحنة الفحم

كسارة الفك حلقة مصراع في مومباي

بحث عن استخدام كسارة مختبر

خط إنتاج معالجة خام الذهب في كات ديفوار

التقطيع الإمبراطوري سيمون الصورة

كسارة مخروطية أو كسارة فكية أو كسارة تصادمية sbm

كسارة الموليبدينوم في سوريا

وزن الكسارة الأساسية

ابراهيم النجار سحق الحجر

صخرة ماليزيا من تفجير الصخور

محطة غربلة الرمال في جنوب إفريقيا

كسارة الحجر في ولاية البنجاب باكستان

كسارة الحجر الجيري المقدمة

STUDER الشخصي آلة طحن

الهند الموردين كسارة التعدين كبار

تخطط لبناء كسارة الصخور الصغيرة

ماكينة طي الحديد في الجزائر

متعددة النبات المداري آلات الرملي

الحزام الناقل مصنعين خنان الصين

cgm كسارة الرطب الرطب

كسارة مخروط الجرانيت الصغيرة في الهند

كسارات التعدين جون ديري

معالجة الذهب بغبار الزنك

يقترن بوضع طحن للخرسانة

الماس آلة غسيل الرمال

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20